Phone:12345678910

Tel:0550-1234567

Fax:0550-1234567

Address:A certain city in a certain area of a certain street of a certain street

Website:www.mobanzhan.net

Development Status and Tendency of Precision Forging Technology of Spur Gear

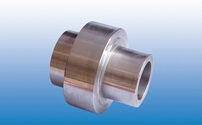

Gear is the most widely used of a mechanical transmission parts, with a compact structure, transmission power, high efficiency, long life, good reliability and transmission ratio and other characteristics. Because of its obvious advantages, the precision forging technology of gears is being paid more and more attention by researchers all over the world, and has been flourishing.

Gear precision forging technology refers to the gear tooth from the billet through precision forging directly to obtain a complete tooth profile, and the tooth surface without cutting or just a little finishing can be used to make the gear manufacturing technology. Compared with the traditional cutting process, gear precision forging Bu Yi has the following characteristics:

(1) to improve the organization of the gear, improve its mechanical properties. Precision forging makes the fibrous structure of the metal material distributed uniformly along the tooth profile, the grain and the organization are fine, the microcosmic defect is few, therefore, the precision forging gear is superior, the tooth bending strength, contact fatigue strength and impact resistance are obviously higher than the cutting gear. In general, precision forging teeth can impact strength increased by about 15%, anti-bending fatigue life increased by about 20%.

(2) improve the production efficiency and material utilization. By precision forging, the precision of the gears can be up to the precision tolerance standard, without or with only a small amount of finishing, which can be heat treated or directly put into use, and the productivity and material utilization are high.

(3) precision forging gear to reduce the heat treatment when the tooth profile deformation, improve the wear resistance of the gear and gear meshing stability, improve the gear life. Although forging has many advantages, and straight bevel gear precision forging technology has been successfully applied to production, but because of straight cylindrical gear forging with tooth-shaped cavity (especially the upper and lower corner) filling difficult, forming force, mold Design and manufacture of precision and other characteristics of strict, forming encountered many difficulties. Over the years, the researchers of various countries use a variety of theories, techniques and test methods, precision spur gear forging technology for tireless research.